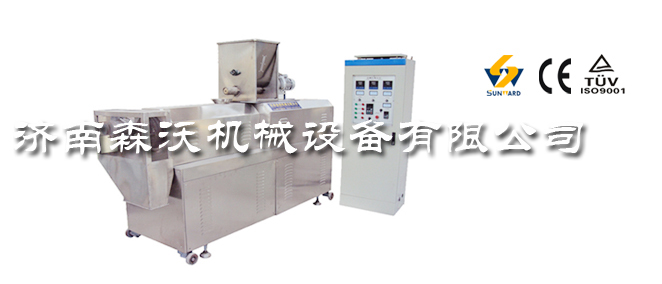

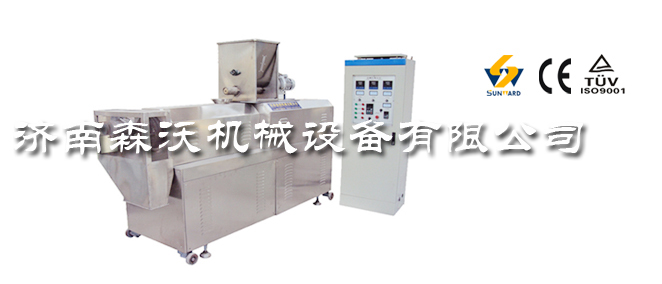

Extrusion equipment is the most

important part for soy protein food production, rice production lines or

etc. Only in understanding the extrusion equipment correct operation

method, and the strict operation, then the extrusion equipment can be

play the biggest role.

1.First,before the extrusion equipment work,remove the

head,movement,lead screw and other components. Carefully cleaning up the

oil stain on the movement and lead screw. Then Dry, refitted and start

running one minute --2 minutes,add the raw material to feed port slowly,

When the raw material reach about a handful can filling the screw cab

head, stop feeding, rubbing preheat. Stay head temperature rise,the

machine cavity increasing, the nozzle begin to spray can feeding.

Because the cavity can not reach the normal temperature and pressure

now, feeding should be gradually increase.

2.In order to avoid the spiral groove blocked,feeding should be

continuous and evenly, the dry material should be dry,when find the

spiral groove blocked,don’t stop the equipment immediately,should run a

while after stop feeding,until smells anxious burnt stop. In this way

can avoid nozzle, screw cab head sleeve bearing seizure. If nozzle,

screw cab head sleeve bearing seizure,don’t banging hard hit,can removed

from the machine,Put it in the fire burning for a while, you can remove

it.

3.

Extrusion equipment early work

nozzle hole can’t spray the molding products,it is often caused by the

nozzle temperature is too high, the reason is that the raw material is

too dry, have something in the spiral groove or feed interruption

caused.Should find the reason under the different

situation,troubleshooting. After stop feeding,let the machine idle one

minute,after drained inside the material then stop. Then remove the

nozzle, screw covers with hot, remove residue inside the extruder, clear

the nozzle, to prepare for reuse.

Extrusion Equipment is a mix, cut, heating, kneading and cooling and

forming together a variety of processes, has been widely used in modern

industrial production. Please used the extrusion machine with correct

method and make the best of it.

Jinan Sunward Machinery Co.,Ltd is a professional

Puffing corn manufacturer. Our company could also supply many other equipments&parts including

puffed food processing line,

Ornamental fish feed processing line, textured soy protein processing

line, pet food processing line, floating fish feed processing line,

puffed feed processing line, nutritional rice processing line,

corn flakes processing line,

Denatured starch processing line, core filling food processing line,

puffed leisure food processing line, Fried puffed food processing line,

Kurkure food processing line, breakfast cereal processing line, puffed

nutritional powder processing line, bread crumbs processing line and so

on.

Tel:0086-531-67877802

Tel:0086-531-67877802  Cel:+8618865912025(Whatapp)

Cel:+8618865912025(Whatapp)  E-mail:carol@cnsunward.com

E-mail:carol@cnsunward.com