Five advantages of extruded feed

DATE:2016/06/24

Five advantages of

extruded feed

Feed ingredients often contain harmful

microorganisms, such as aerobic organisms, neutrophilic bacteria, E.

coli, mold, salmonella, etc., animal feed ingredients in relatively high

levels.With puffing, high temperature, high humidity, high pressure can

kill most of the harmful microorganisms. Data shows that the number of

E. coli per gram of material up to 10 000 and less than 10 remaining

after puffing. Salmonella will be basically killed after puffing at a

high temperature above 85 ℃. This can helps to maintain water quality

and reduce adverse environmental factors for aquaculture, while reducing

the mortality of aquatic animals.

In

artificial breeding conditions, stocking density increases means the

higher the rate of return means that farmers get. When the breeding

density units improving, fish in aquaculture water space narrowing,

water quality requirements are much higher than the level necessary to

the natural environment. Using extruded feed can reduce the feed

conversion ratio, so that the bait into the water and excreta greatly

reduced, it is possible to make the stocking density increased

significantly.

Extruding processing can improve the stability of the raw material by reducing the bacterial

content and oxidation. When sulfate, cooling extrusion product, feed

water activity (AW) is reduced to 0.6, even up to 0.4, which is

equivalent to a moisture content of 8% to 10%, better improving the

storage stability of feed.

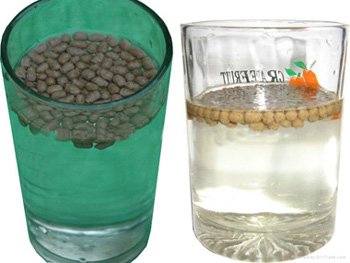

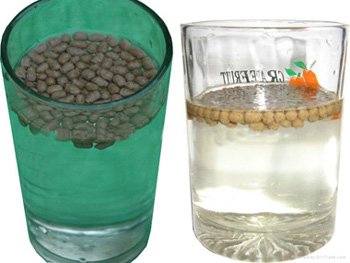

Aquatic extruded feed can floating longer time in the water.

Feeding without dedicated feeding station, you can just point feeding.

Then fish will float to the surface. Fish will float to the surface of

water to eating fee. So you can directly observe the fish feeding

situation and adjust the amount of feeding. Also you can keep abreast of

the growth and health of fish stocks. Therefore, the use of aquatic

extruded feed contributes scientific feeding and management, which saves

a lot of time, but also raise labor productivity.

Jinan Sunward Machinery Co., Ltd. is professional manufacturer

specialized in production of extruded equipment. We have other

machines: food extrusion machines,

ornamental fish feed machine, tissue protein production line, pet food

production lines, floating fish feed production line, extruded feed

production line, nutrition rice processing machine corn artificial rice

machine, modified starch production line, core filling food production

lines, puffed snack food production line, fried puffed food production line,

kurkure production lines, breakfast cereals production machine,

expanded nutrition powder production line, bread crumbs machine and such

as extrusion machine and auxiliary equipment.

Tel:0086-531-67877802

Tel:0086-531-67877802  Cel:+8618865912025(Whatapp)

Cel:+8618865912025(Whatapp)  E-mail:carol@cnsunward.com

E-mail:carol@cnsunward.com