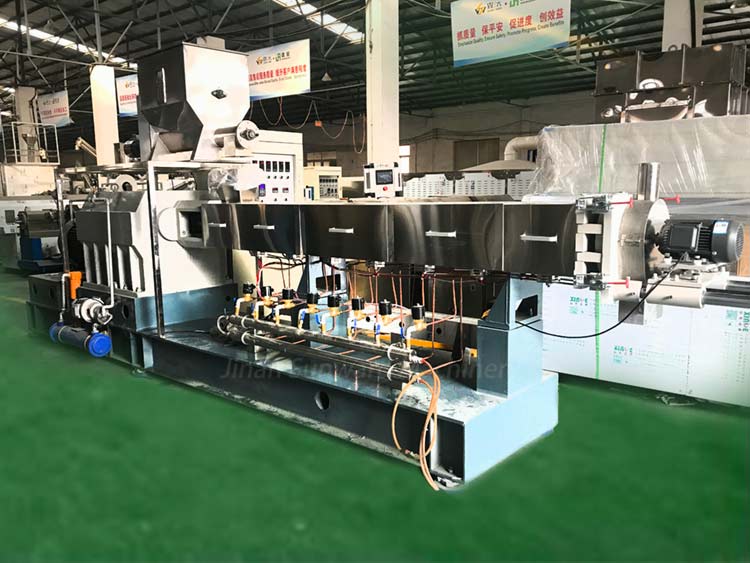

First show a picture of a rice extruder with an output of more than 800kg per hour.

There are many types of extruders according to their uses. There are extruders for puffed food, extruders for feed, and extruders for high-moisture protein. Therefore, according to different functions, the structure of the corresponding extruder is also different. The main difference is the length-diameter ratio of the screw. The length-to-diameter ratio of the screw determines what product to make. Secondly, it is divided from the advanced degree of the process and the iteration of the extruder. The original extruder was a single-screw extruder, then a twin-screw extruder, and now there is a 3-screw extruder. However, in terms of performance and stability, twin-screw is currently the best. Because the practicability of the single screw is too narrow, it is only suitable for a small amount of products, and the current technology of the three screw is not very mature, so the twin screw extruder is currently the most widely used. In fact, the single-screw extruder is very suitable for making artificial rice, but the output is too small, and it can only reach the output of 100kg/h. Although ordinary twin-screw can be used to make artificial rice, the shape and color of the rice produced are not ideal. Therefore, according to this pain point, our company has intensified research and development efforts, and finally, after unremitting efforts to break through the technical difficulties, we have produced a new rice extruder that can not only produce perfect artificial rice, but also have a large output. Below are some details some of the new extruders and production process.

Copyright © Jinan Sunward Machinery Co., Ltd. 2014 All rights reserved

Tel:0086-531-67877802

Tel:0086-531-67877802  Cel:+8618865912025(Whatapp)

Cel:+8618865912025(Whatapp)  E-mail:carol@cnsunward.com

E-mail:carol@cnsunward.com

①Factory Address --Xiaoluzhuang Industrial Park, Jinan City, China

②Room 1304,Shanxin Mansion,Qizhou Road,Huaiyin District,Jinan city,Shandong Province,China