Extrusion machinelife: different manufacturers due to the twin-screw extruder drive mechanism, structural characteristics, use of materials, processing techniques, different, very different life. Extruder in the selection, the first should be noted that the overall structural design is reasonable, the parts manufacturing process, the selection is excellent, the wear resistance of wearing parts such as how; Secondly, we should pay attention to the power transmission mechanism design is reasonable, it can effectively reduce the transmission process energy consumption.

Operability

Extrusion processing is generally manual or semi-automatic operation, it is to consider the labor intensity twin screw extruder, the operation is convenient, emergency measures are perfect. Such as whether a large twin-screw extruder equipped with a lifting mechanism and screw removal tool for easy replacement of a spiral or barrel; whether spilled material means to preclude the blocking machine conditioner to prevent their access to the material in the expanded organization; expanding external heating measures are completely safe and reliable; whether jacket pressure test detection.

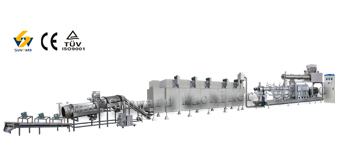

Jinan Sunward Machinery Co.,ltd is professional puff food etruder manufacture factory, our main equipment including: snack food machinery, fish food machinery, textured soy processing line, pet food processing line, floating fish food processing lien, nutrition rice processing line, artificial rice processing line, modified starch processing line, core filling snack processing line, puff snacks processing line, fried snack processing line. Kurkure processing line, breakfast cereal processing line, nutrition puff powder processing line, bread crumb processing line and other auxiliary machinery www.cnsunward.com

Copyright © Jinan Sunward Machinery Co., Ltd. 2014 All rights reserved

Tel:0086-531-67877802

Tel:0086-531-67877802  Cel:+8618865912025(Whatapp)

Cel:+8618865912025(Whatapp)  E-mail:carol@cnsunward.com

E-mail:carol@cnsunward.com

①Factory Address --Xiaoluzhuang Industrial Park, Jinan City, China

②Room 1304,Shanxin Mansion,Qizhou Road,Huaiyin District,Jinan city,Shandong Province,China