Features:

1. Frying Pellet Processing Line adopts flour, corn starch and potato starch as raw material, makes food through the process of extruding, cooking, shaping, drying and frying.

2.By choosing different dies, you can make different shapes food such as shell, screw, square tube, round tube, lotus root slices etc. The food is very popular in market.

3. This processing line has the advantage of rational design, high automatic degree and accuracy control.

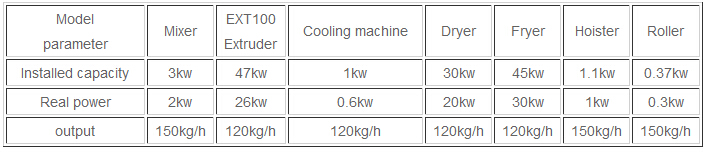

4. The model is EXT100, the output is 100-120kg/h.

5. The main body material is stainless steel, which is easy to be cleaned.

6. The screws material is 38CrMnAl, which is wear-resisting.

7. Our project is turn-key. We will send our engineer to your factory, install and debug the equipments, and train your operators.

8.The processing line needs two workers to operate.

9.Around 100 square meters plant is suggested for this line. The length is no less than 20 meters.

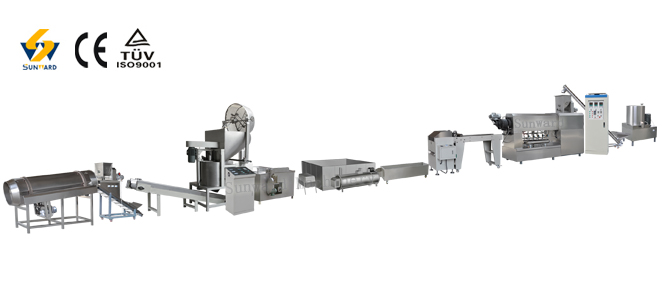

10.Process flow: (Raw material)---mixing---extruding & puffing---cooling---drying---frying---hoisting---flavoring--- (packing)

11. Machines: Mixer---Extruder---Cooling bed---Drying bed---Fryer---Hoisting and flavoring machine---Roller--- (Packing machine)

12.The temperature and rotating speed can be controlled and adjusted.

Technical Parameters:

Related products:

Related links:

Authentic Italy pasta making with the right machine and right technique

| Your Country: | |

| Your Name: | * |

| Your Phone: | |

| Interested Products: | |

| Your E-mail: | * |

| Message: | * |

| Verification code: |

|

Copyright © Jinan Sunward Machinery Co., Ltd. 2014 All rights reserved

Tel:0086-531-67877802

Tel:0086-531-67877802  Cel:+8618865912025(Whatapp)

Cel:+8618865912025(Whatapp)  E-mail:carol@cnsunward.com

E-mail:carol@cnsunward.com

①Factory Address --Xiaoluzhuang Industrial Park, Jinan City, China

②Room 1304,Shanxin Mansion,Qizhou Road,Huaiyin District,Jinan city,Shandong Province,China