Description:

Pet food is a nutritious food specially provided for dogs, cats, fish and other pets. It is a high-end animal food between human food and traditional livestock and poultry feed. Usually what we call pet food is dry puffed pet food, which is a kind of commercial pet food.

The pet food produced by the extrusion process has the following advantages:

1. Improve the palatability of pet food;

2. Change or improve the nutritional value of pet food;

3. Improve pet's digestion and absorption rate of food;

4. Change the shape and structure of pet food to make it easy for pets to eat;

5. Change the content of different nutritional indicators of pet food, such as reducing the moisture content in order to improve the shelf life of the food, which is conducive to storage;

6. Change the bulk density of food, squeeze granulation, briquetting to increase the bulk density of food;

7. Kill all kinds of molds, salmonella and other harmful substances, and improve the safety and hygiene of pet food.

Extrusion can be divided into two types, one is the dry-type extrusion method, and the second is the wet-type extrusion method.

Dry extrusion requires the addition of water to the raw materials during the production and processing. The raw materials do not undergo pre-conditioning treatment before entering the puffing bin. During the puffing process, the raw materials pass through the screw and barrel under the action of mechanical extrusion, which will generate some heat. The heating ring provides additional heat to ensure good maturation of the food.

The difference between wet-puffing method and dry-puffing method is that the raw materials are pretreated in advance before entering the puffing bin, and the temperature is increased by steam, and pre-cured. The so-called conditioning refers to the use of steam to heat and moisturize pet food raw materials to pre-gelatinize starch, protein denature, and soften raw materials in the raw materials, which is beneficial to improve the puffing and granulating effect of pets and improve the puffing quality.

Our pet food machines have the capability of these two puffing processes. But in general, small-capacity machines only have the capability of dry puffing.

Features of our pet food machines :

1. Visual automatic temperature control system to make temperature control more intuitive and parameters more accurate.

2. Pet Food Processing Line has wide raw material range, can adopt fresh/frozen meat/fish, bones, animal offals, grain flour, bone meal, fish meal, etc. as raw materials.

3. Different shapes can be made by adjusting the dies from extruder

4. Output can be 1ton---12ton/h

5. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

6. All contact parts of the machines are made of stainless steel.

7. Reasonable design, flexible configuration, maximize space utilization (the production line can be designed as a horizontal or vertical structure, and can be arranged in an L-shape or U-shape.

8. High-automation. The raw material processing system, extrusion and puffing system, drying system, seasoning system and packaging system can be integrated to achieve intelligent control, improve production efficiency and greatly reduce labor costs.

9. Self-cleaning, when stopping, can be cleaned without disassembling.

Flow chart:

Raw material processing system---Extrusion system----Drying system----Flavoring system--Cooling system--Packing system

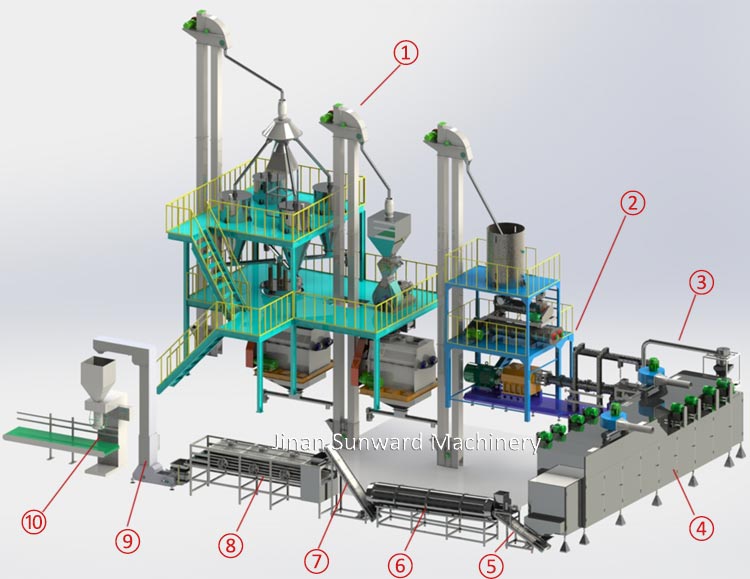

① The raw material processing system of the production line. Its function is raw material pulverizing, weighing and mixing.

② The twin-screw extruder is used for curing, puffing, and forming raw material (There is a pre-conditioner contained in the extruder that is used for pre-conditioning and pre-heating the raw materials through steam, the raw materials are softened, which is more conducive to molding, and at the same time reduces the wear and tear of the raw materials to the extruder machine).

③ The Air conveyor is used to deliver fish feed from the extruder to the dryer.

④ The dryer is used to dry fish feed. According to the different energy sources, we have electric dryers, steam dryers, oil/gas dryers for you to choose from.

⑤ The Hoister is used to deliver fish feed from the dryer to the flavoring machine.

⑥ The flavoring machine is used to spray the surface of the fish feed with drugs for treating fish diseases and attractants, etc.

⑦ This is another Hoiser which is used to deliver fish feed from the seasoning machine to the cooling machine.

⑧ The Cooling machine is used to cool fish food before packing.

⑨ The Z Shape Hoister is used to deliver fish feed from the cooling machine to the packing machine.

⑩ The packing machine is used to pack fish food in different bags. We have fully automatic and semi-automatic packing machines for you to choose from. Powder, granular and blocky products can be packed by the packing machines.

| Model | TSE90 | TSE95 | TSE120 | TSE140 | TSE160 |

| Installed Powder | 160kw | 180kw | 290kw | 350kw | 415kw |

| Production Capacity | 800-1200kg/h | 1000-2000kg/h | 3000-5000kg/h | 5000-8000kg/h | 8000-120000kg/h |

| Dimension | 40*2.0*3.0m | 45*2.0*3.2m | 60*3.0*3.5m | 70*3.8*4.0m | 78*3.8*4.0m |

Video of Production Dog Food:

Sample products:

Related Products:

Tow-color Pet Food Extruder

Pet Treats Processing Line

Small Pet Food Processing Line

| Your Country: | |

| Your Name: | * |

| Your Phone: | |

| Interested Products: | |

| Your E-mail: | * |

| Message: | * |

| Verification code: |

|

Copyright © Jinan Sunward Machinery Co., Ltd. 2014 All rights reserved

Tel:0086-531-67877802

Tel:0086-531-67877802  Cel:+8618865912025(Whatapp)

Cel:+8618865912025(Whatapp)  E-mail:carol@cnsunward.com

E-mail:carol@cnsunward.com

①Factory Address --Xiaoluzhuang Industrial Park, Jinan City, China

②Room 1304,Shanxin Mansion,Qizhou Road,Huaiyin District,Jinan city,Shandong Province,China