High-moisture protein is a vegetable protein product with a moisture content of ≥50%. The main raw material is vegetable protein extracted from soybeans, peas, wheat and other plants. According to the biochemical composition and three-dimensional structure of meat, modern food processing technology and equipment are used. , which accurately simulates the composition and structure of meat, making it a type of plant-based protein product that has similar characteristics to livestock, poultry, and fish in terms of texture, structure, chewiness, and even flavor. Plant-based meat products feature high protein, low fat, low carbohydrate, 0 cholesterol, and 0 trans fatty acids, helping people transition to a healthier diet. What's more worth mentioning is that compared to meat, plant-based meat can also help reduce environmental damage from the production process. Livestock is the second-largest source of greenhouse gas (GHG) emissions after fossil fuels and a contributor to deforestation, water and air pollution, and biodiversity loss. New research shows that reducing meat consumption and switching to a plant-based diet can reduce our personal carbon footprint by up to 35%, and its products are well-received and recognized by consumers for their delicious, healthy and environmentally friendly properties. Industry insiders believe that the market for plant protein may exceed that of animal protein in the future.

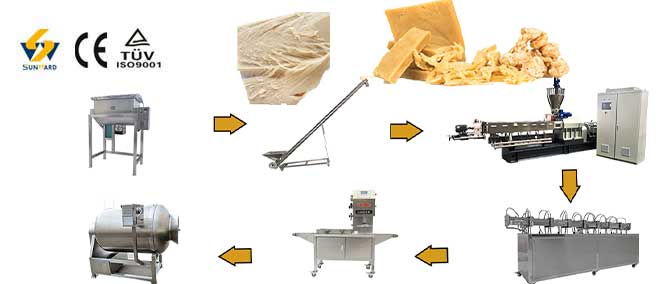

Batching---Mixing---Extrusion---Cooling---Shaping---Cutting

Production line flow chart:

Mixer---Screw conveyor---HMMA extruder---Shaper---Cutter

①Mixer:

Small production lines can use simple powder mixers, which are characterized by small output and need to match raw materials in a certain proportion manually; large production lines can use automatic feeding system, which is characterized by complete automation (automatic weighing and batching and Mixed materials), the output is large.

② The screw conveyor is used to transfer the processed raw materials from the mixer to the extruder

③ The extruder is used to used to reconstitute proteins

④ The shaper is used to cool and shape the protein

⑤ The cutter is used to cut protein into different size

| Model | Installed Power | Capacity | Dimension |

| TSE65-W | 74kw | 100-150kg/h | 15×1.5×2.2m |

| TSE75-W | 160kw | 400-500kg/h | 22×1.7×2.2m |

previous:Three-screw extruder

| Your Country: | |

| Your Name: | * |

| Your Phone: | |

| Interested Products: | |

| Your E-mail: | * |

| Message: | * |

| Verification code: |

|

Copyright © Jinan Sunward Machinery Co., Ltd. 2014 All rights reserved

Tel:0086-531-67877802

Tel:0086-531-67877802  Cel:+8618865912025(Whatapp)

Cel:+8618865912025(Whatapp)  E-mail:carol@cnsunward.com

E-mail:carol@cnsunward.com

①Factory Address --Xiaoluzhuang Industrial Park, Jinan City, China

②Room 1304,Shanxin Mansion,Qizhou Road,Huaiyin District,Jinan city,Shandong Province,China